Technical Data

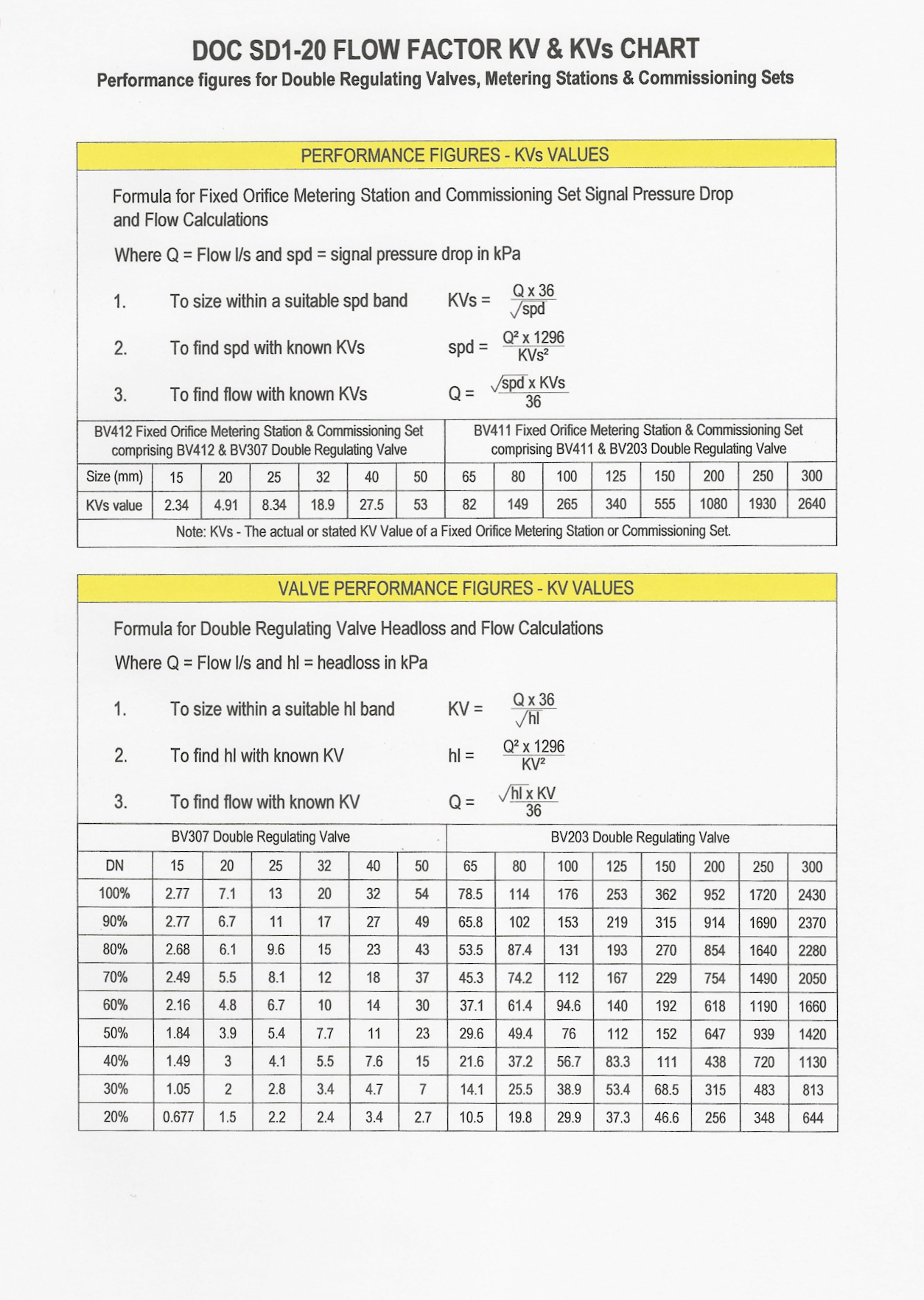

Flow factor KV & KVs Chart

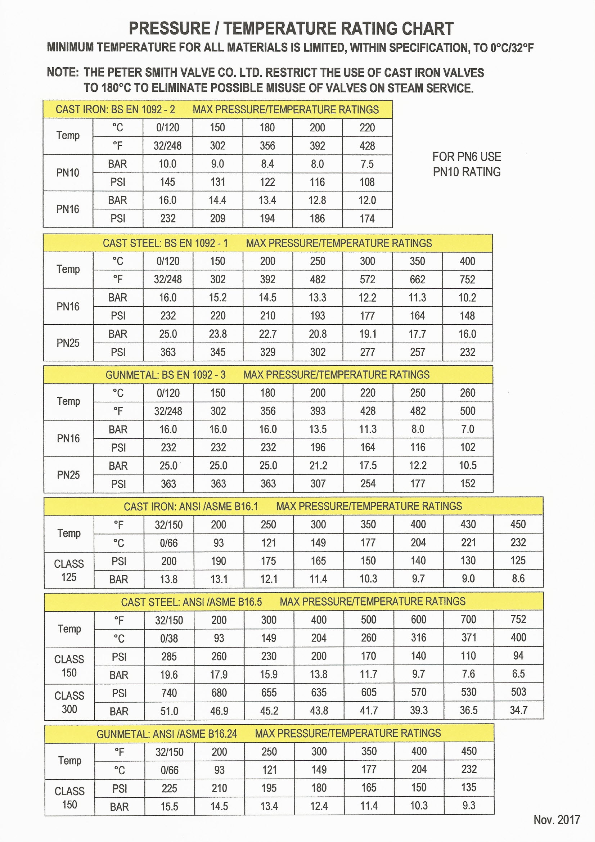

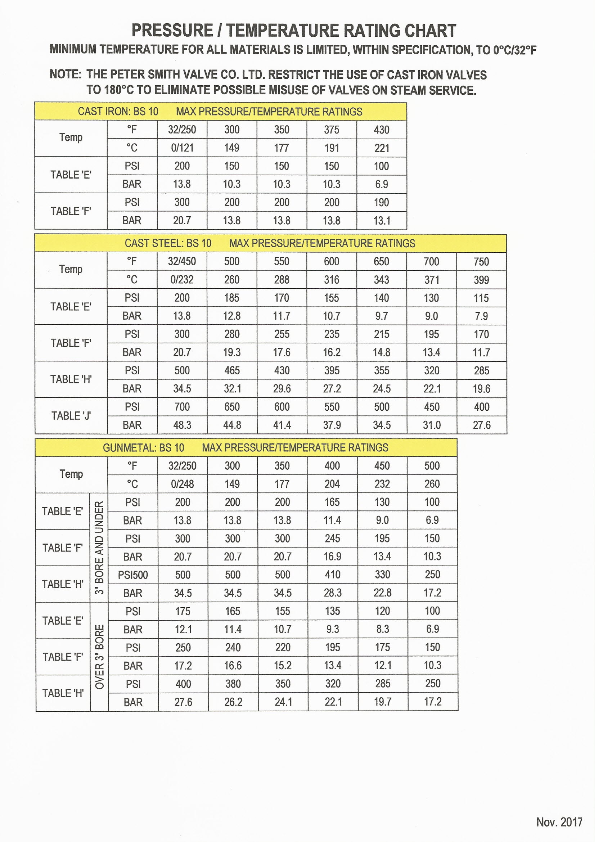

Technical Data

Health & Safety

BS 18001

The Peter Smith Valve Company Ltd is operating an Occupational Health and Safety Management System and has been registered by BSI to BS OHSAS 18001 certificate no. 512384

GENERAL STATEMENT

Valves from our range when properly selected, handled, installed and maintained will not present a health hazard or cause injury provided they are used for their specified purpose and pressure/temperature range.

SELECTION, HANDLING AND INSTALLATION

2.1.1 It should be ascertained if any Codes of Practice or Mandatory requirements of statutory bodies apply to the particular installation.

2.1.2 It is essential to select valves with a pressure/temperature rating compatible with all anticipated system maximum working conditions.

2.1.3 Valves should be correctly sized to avoid high fluid velocity which causes noise and erosion.

2.1.4 Valve materials should be selected for optimum compatibility with known corrosion problems and planned maintenance should include regular inspections in severe cases.

2.1.5 Valves for potable water should be selected from The Water Research Centre publication ‘’Water fittings and Materials Directory’’.

2.2.1 Cast Iron and Gunmetal valves are easily damaged by impact and must not be dropped or thrown.

2.2.2 Mechanised handling equipment must be used for heavy valves which must not be lifted by the handwheel or lever alone.

2.3.1 Valves may malfunction (or cast iron even fracture) if subject to torsional stress caused by expansion of any associated pipe forming a radius arm.

2.3.2 The flow must be in the direction of any indication marked on the valve.

2.3.3 Further guidance may be found in BS 6683 ‘’Installation and use of Valves’’.

MAINTENANCE

3.1 Maintenance should include regular inspection for:

(a) loose nuts and bolts (e.g. handwheel)

(b) correct tension on the gland

3.2 Note: some PTFE components release harmful vapours when burned.